A.Manual loading

Qhib lub hau ntawm rab riam thiab tuav cov ntaub ntawv ncaj qha, lossis ua ib lub qhov ntawm lub hau thiab ntxiv cov ntaub ntawv manually.

B. Los ntawm cov ntsia hlau conveyor

Cov ntsia hlau feeder tuaj yeem xa cov khoom siv hmoov thiab granule los ntawm ib lub tshuab mus rau lwm qhov. Nws muaj txiaj ntsig thiab yooj yim. Nws tuaj yeem ua haujlwm hauv kev koom tes nrog cov tshuab ntim khoom los tsim cov kab ntau lawm. Yog li nws yog dav siv nyob rau hauv ntim kab, tshwj xeeb tshaj yog semi-auto thiab tsis siv neeg ntim kab. Nws yog tsuas yog siv nyob rau hauv conveying hmoov cov ntaub ntawv, xws li cov mis nyuj hmoov, protein hmoov, mov hmoov, mis nyuj tshuaj yej hmoov, khoom haus, kas fes hmoov, qab zib, qabzib hmoov, zaub mov additives, pub, kws raw cov ntaub ntawv, tshuaj tua kab, zas xim, tsw, fragrances thiab thiaj li nyob.

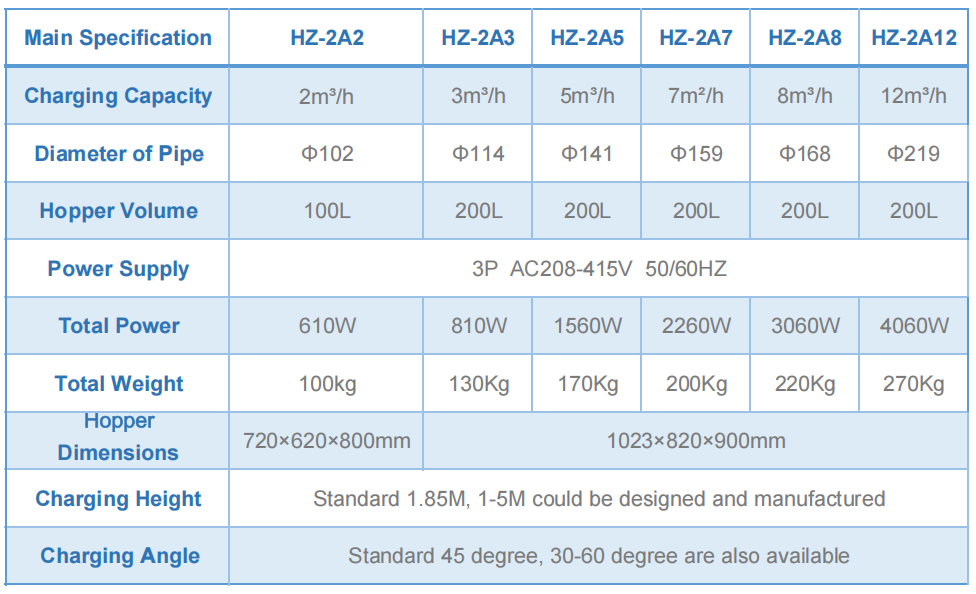

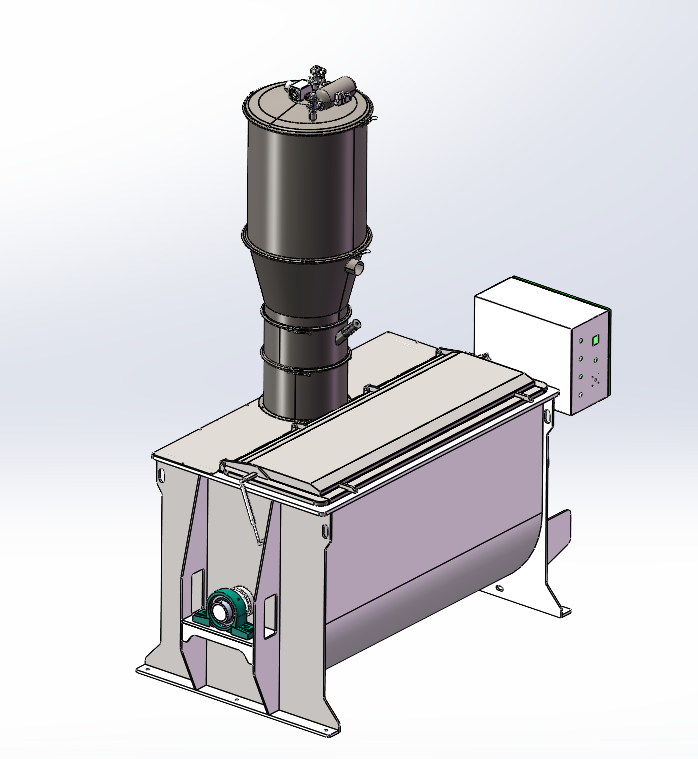

Screw conveyor yog tsim los ntawm Pub lub cev muaj zog, vibrator lub cev muaj zog, hopper, raj, thiab ntsia hlau. Tus qauv qauv nrog 45 degree them lub kaum ntse ntse thiab 1.85 m them qhov siab. Lub peev xwm muaj 2m3 / h, 3 m3 / h, 5 m3 / h, 8 m3 / h thiab lwm yam ceev. Lwm tus tuaj yeem hloov kho.

Txoj haujlwm ua haujlwm:

Cov ntsia hlau feeder txav cov khoom nce mus los ntawm kev kaw tag nrho helical rotating ncej. Qhov ceev ntawm cov ntsia hlau lub cev yog siab tshaj qhov zoo tib yam ntsia hlau conveyor. Nyob rau hauv qhov kev txiav txim ntawm lub zog centrifugal, cov khoom siv thiab cov casing tsim kev sib txhuam, uas tiv thaiv cov khoom los ntawm kev tig nrog cov ntsia hlau hniav thiab kov yeej qhov teeb meem ntawm cov khoom. Poob lub ntiajteb txawj nqus, yog li paub qhov inclined lossis ntsug conveying ntawm cov ntaub ntawv.

C.Los ntawm lub tshuab nqus tsev conveyor

Lub tshuab nqus tsev feeder yog siv lub tshuab nqus tsev twj tso kua mis tawm cua. Lub inlet ntawm cov khoom nqus kais thiab tag nrho cov system yog ua kom nyob rau hauv lub nqus tsev vacuum. Cov hmoov nplej ntawm cov khoom yog absorbed rau hauv cov khoom siv kais nrog cua ambient thiab tsim los ua cua ntws nrog cov khoom. Dhau cov khoom nqus cov raj, lawv tuaj txog rau lub hopper. Cov huab cua thiab cov khoom sib cais hauv nws. Cov ntaub ntawv sib cais raug xa mus rau cov khoom siv tau txais. Lub chaw tswj hwm tswj qhov "on / off" lub xeev ntawm pneumatic triple valve rau kev pub lossis tso tawm cov ntaub ntawv.

Nyob rau hauv lub tshuab nqus tsev feeder lub compressed cua opposite tshuab yog haum. Thaum tso tawm cov ntaub ntawv txhua zaus, cov pa compressed pulse oppositely tshuab lub lim. Cov hmoov uas txuas rau saum npoo ntawm lub lim yog tshuab tawm kom ntseeg tau tias cov khoom siv absorbing zoo li qub.

Lub tshuab nqus tsev pneumatic lub tshuab nqus tsev vacuum siab dhau los ntawm lub tshuab nqus tsev siv compressed cua kom ua tiav cov khoom xa tuaj, tsis muaj lub tshuab nqus tsev twj, muaj cov qauv yooj yim, me me, tsis muaj suab nrov, yooj yim los tswj, tshem tawm cov khoom zoo li qub thiab raws li GMP cov kev cai, thiab lwm yam.. Lub tshuab nqus tsev siab siab ntawm lub tshuab nqus tsev nqus tsev vacuum, thiab kev tiv thaiv kev sib xyaw ntawm cov khoom siv thiab cov khoom sib xyaw. blender tsis siv neeg pub khoom noj ntawm kev xaiv.

Kev sib piv ntawm cov ntsia hlau conveyor thiab ntsia hlau feeder

Qhov zoo ntawm lub tshuab nqus tsev feeder feem ntau suav nrog:

1) Kev thauj mus los tsis muaj plua plav kaw tuaj yeem txo cov pa phem thiab txhim kho qhov chaw ua haujlwm. Nws kuj txo cov pa phem ntawm ib puag ncig thiab cov neeg ua haujlwm rau cov khoom siv thiab txhim kho kev huv.

2) Muaj qhov chaw me me, tuaj yeem ua tiav cov hmoov thauj mus los hauv qhov chaw me me, ua rau qhov chaw ua haujlwm zoo nkauj thiab dav.

3) Tsis txwv los ntawm qhov ntev lossis luv luv, tshwj xeeb tshaj yog tsim rau kev thauj mus los ntev.

4) Txo kev siv zog ua haujlwm thiab txhim kho kev ua haujlwm. Nws yog thawj qhov kev xaiv rau feem ntau cov hmoov txheej kev thauj mus los.

Disadvantages muaj xws li:

1) Tsis haum rau cov khoom siv uas ntub dej, nplaum, lossis hnyav dhau.

2) Cov kev xav tau rau qhov loj me thiab qhov ntom ntom ntawm cov khoom yog nruj heev. Rau cov khoom uas muaj cov duab sib txawv los yog qhov ntom ntom, qhov kev xa khoom zoo yuav raug cuam tshuam zoo heev.

Qhov zoo ntawm cov ntsia hlau feeders muaj xws li:

1) Cov kev xav tau rau qhov loj me thiab qhov ntom ntom ntawm cov ntaub ntawv yog qhov xoob. Ntev npaum li cov ntaub ntawv tuaj yeem nkag mus rau hauv cov kauv du, lawv tuaj yeem thauj mus rau qhov chaw siab yam tsis muaj qhov sib txawv.

2) Nws tsis yooj yim dua los ntxuav thaum hloov cov khoom siv, thiab nws yooj yim dua li lub tshuab nqus tsev.

Lub ntsiab tsis zoo yog:

1) Tsis haum rau kev thauj mus los ntev, vim tias nws txoj kev thauj mus los yuav txo qis thaum qhov kev ncua deb nce.

2) Cov hmoov av lossis cov ntaub ntawv ya tuaj yeem ua rau muaj plua plav paug.

Yog li lub tshuab nqus tsev feeders thiab ntsia hlau feeders txhua tus muaj lawv tus kheej cov xwm txheej thiab cov kev txwv. Cov feeder twg xaiv yuav tsum tau ua tiav raws li cov yam ntxwv xws li cov khoom siv tshwj xeeb, ib puag ncig tsim khoom, thiab cov kev xav tau ntawm kev tsim khoom.

Yog tias koj muaj lus nug ntxiv txog lub hauv paus ntsiab lus ntawm ribbon blender, thov koj xav tiv tauj peb rau kev sab laj. Cia koj cov ntaub ntawv tiv tauj, thiab peb yuav tiv tauj koj li ntawm 24 teev los pab thiab qhia meej txog cov kev tsis txaus siab uas koj muaj.

Post lub sij hawm: Mar-06-2025