-

V hom MIXING tshuab

Lub tshuab v-shaped tov khoom no yog tsim los sib tov ntau tshaj ob hom hmoov qhuav thiab granular cov ntaub ntawv hauv kev lag luam tshuaj, tshuaj thiab zaub mov. Nws tuaj yeem nruab nrog quab yuam agitator raws li tus neeg siv yuav tsum tau ua, thiaj li tsim nyog rau kev sib xyaw hmoov zoo, ncuav mog qab zib thiab cov ntaub ntawv uas muaj qee yam dej noo. Nws muaj cov chav ua haujlwm txuas nrog ob lub tog raj kheej ua "V" zoo li. Nws muaj ob qhov qhib rau sab saum toj ntawm "V" lub tank uas yooj yim tshem tawm cov ntaub ntawv thaum kawg ntawm kev sib tov. Nws tuaj yeem tsim cov khoom sib xyaw ua ke.

-

Muaj peev xwm sau thiab ntim cov kab ntau lawm

Qhov ua tiav tuaj yeem sau thiab ntim cov kab ntau lawm nta Screw Feeder, Ob Chav Ribbon Tov Khoom, Vibrating Sieve, Hnab Tshuab xaws, Lub Hnab Loj Auger Filling Tshuab thiab Cia Hopper.

-

4 Lub taub hau Auger Filler

Ib tug 4-lub taub hau auger muab tub lim yog anyiaj txiaghom ntim tshuab siv nyob rau hauv cov zaub mov, tshuaj, thiab tshuaj industries rausiabraugntsuas thiabsau cov hmoov qhuav, los yogme mecov khoom granular rau hauv ntim xws li lub raj mis, jars.

Nws muaj 2 txheej ntawm ob lub taub hau filling, ib qho kev ywj pheej motorized saw conveyor mounted ntawm lub hauv paus ruaj khov thiab ruaj khov, thiab tag nrho cov khoom siv tsim nyog kom txav tau yooj yim thiab tso cov thawv ntim rau ntim, xa cov khoom xav tau, ces txav cov ntim ntim sai sai mus rau lwm cov khoom siv hauv koj cov kab (xws li, capping tshuab, labeling tshuab, thiab lwm yam). Nws haum ntau rau covfluiditylos yog cov ntaub ntawv uas tsis muaj fluidity, xws li mis hmoov, albumen hmoov, tshuaj, condiment, dej haus, dawb qab zib, dextrose, kas fes, tshuaj tua kab ua liaj ua teb, granular additive, thiab hais txog.

Cov4- taub hauauger filling tshuabyog cov qauv compact uas siv qhov chaw me me, tab sis lub filling ceev yog 4 npaug tshaj ib lub taub hau auger, zoo heev txhim kho cov filling ceev. Nws muaj ib tug kev tswj system. Muaj 2 txoj kab, txhua txoj kab muaj 2 lub taub hau uas tuaj yeem ua 2 txoj kev ywj pheej.

-

TP-A Series Vibrating linear hom hnyav

Linear Type Weigher muaj qhov zoo xws li kev kub ceev, qhov raug siab, kev ua haujlwm ruaj khov mus ntev, tus nqi zoo, thiab kev pabcuam zoo tom qab muag. Nws yog tsim rau hnyav hlais, dov, lossis tsis tu ncua cov khoom lag luam, suav nrog qab zib, ntsev, noob, nplej, noob hnav, glutamate, taum kas fes, hmoov nplej, thiab lwm yam.

-

Semi-automatic Lub Hnab Loj Auger Filling Tshuab TP-PF-B12

Lub hnab loj hmoov filling tshuab yog cov khoom siv high-precision industrial tsim los ua kom zoo thiab raug muab cov hmoov ntim rau hauv lub hnab loj. Cov khoom siv no yog qhov tsim nyog rau cov hnab ntim loj loj xws li 10 mus rau 50kg, nrog kev ua haujlwm puv tsav los ntawm lub cev muaj zog servo thiab qhov tseeb tau lees paub los ntawm qhov hnyav sensors, xa cov txheej txheem ua tiav thiab txhim khu kev qha.

-

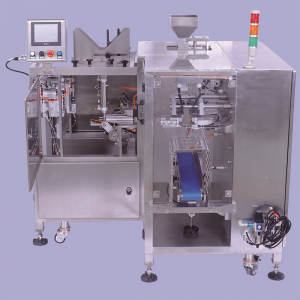

Tsis Siv Neeg Auger Filler

Lub tshuab no yog ua tiav, kev daws teeb meem rau koj cov kab ntau lawm.can ntsuas thiab sau hmoov thiab granular. Nws muaj lub taub hau Filling, ib qho kev ywj pheej motorized saw conveyor mounted rau ntawm lub hauv paus ruaj khov, ruaj khov, thiab tag nrho cov khoom tsim nyog kom txav tau yooj yim thiab tso cov thawv ntim rau kev sau, xa cov khoom xav tau, tom qab ntawd txav cov ntim ntim tawm mus rau lwm cov khoom hauv koj cov kab (xws li cappers, labelers, thiab lwm yam). dej haus, dawb qab zib, dextrose, kas fes, ua liaj ua teb tshuaj tua kab, granular additive, thiab hais txog.

-

Semi-Auto Powder Filling Tshuab

Puas yog koj tab tom nrhiav rau cov hmoov muab tshuaj rau ob qho tib si hauv tsev thiab kev lag luam? Tom qab ntawd peb muaj txhua yam koj xav tau. Nyeem ntxiv!

-

Semi-Automatic Auger Filling Tshuab

Qhov no yog Semi-Automatic qauv ntawm Auger Filler. Nws yog ib hom ntim khoom siv rau dispensing hmoov los yog granular cov ntaub ntawv. Nws ntiav cov auger conveyor kom raug faib cov khoom rau hauv ntim lossis hnab, dav siv hauv kev lag luam xws li zaub mov, tshuaj thiab tshuaj.

· Kev noj tshuaj kom raug

· Kev siv dav dav

· Cov neeg siv-phooj ywg ua haujlwm

· Kev sib raug zoo thiab kev ntseeg siab

· Hygienic Design

· Versatility

-

Ob Chav Ncej Paddle Tov Khoom

Ob chav ncej paddle tov khoom yog hu ua tsis muaj lub ntiajteb txawj nqus tov khoom, ib yam nkaus thiab; nws yog dav siv nyob rau hauv kev sib tov hmoov thiab hmoov, granular thiab granular, granular thiab hmoov, thiab ob peb kua; nws yog siv rau zaub mov, tshuaj, tshuaj tua kab, khoom noj, thiab roj teeb thiab lwm yam.

-

Ntsia Hlau Conveyor

Qhov no yog tus qauv qauv ntawm cov ntsia hlau conveyor (tseem hu ua auger feeder) yog ib hom khoom siv rau kev tuav cov khoom, feem ntau ua haujlwm thauj cov hmoov, granules, thiab cov khoom me me. Nws siv lub rotating helical ntsia hlau hniav kom txav cov ntaub ntawv raws ib lub raj ruaj ruaj los yog trough mus rau qhov chaw uas xav tau. Cov cuab yeej siv no yog siv dav hauv kev lag luam xws li kev ua liaj ua teb, kev ua zaub mov, tshuaj, tshuaj, thiab cov khoom siv.

-

Tib Ncej Paddle Tov Khoom

Lub tshuab nqus tsev twj tso kua mis ib leeg yog tsim los siv rau cov hmoov thiab hmoov, granule thiab granule los yog ntxiv cov kua me me rau kev sib xyaw, nws yog siv dav hauv cov txiv ntseej, taum, nqi lossis lwm yam khoom siv granule, sab hauv ntawm lub tshuab muaj lub kaum sab xis sib txawv ntawm cov hniav cuam tshuam cov khoom yog li sib xyaw.

-

Tsis Siv Neeg Hnab Ntim tshuab

Cov khoom ntim tuaj yeem pom txhua qhov chaw hauv peb lub neej, koj puas paub yuav ntim cov khoom no rau hauv lub hnab? Ntxiv nrog rau phau ntawv qhia, semi-automatic filling tshuab, feem ntau ntawm cov khoom ntim khoom ntim puv puv tshuab kom ua tiav ntim.

Tsis siv neeg lub hnab ntim tshuab tuaj yeem ua tiav lub hnab qhib, zipper qhib, txhaws, ua haujlwm kub sealing. Nws yog dav siv nyob rau hauv ntau lub teb xws li zaub mov kev lag luam, tshuaj lom neeg kev lag luam, kws lag luam, kev lag luam ua liaj ua teb, tshuaj pleev ib ce kev lag luam thiab lwm yam.