Product Description

Cov ntsia hlau feeder tau zoo thiab yooj yim hloov cov hmoov thiab granule cov ntaub ntawv ntawm cov tshuab. Nws tuaj yeem koom tes nrog cov tshuab ntim khoom los tsim cov kab ntau lawm, ua rau nws siv dav hauv cov kab ntim khoom, tshwj xeeb tshaj yog nyob rau hauv semi-automatic thiab tsis siv neeg ntim txheej txheem. Cov khoom siv no feem ntau yog siv rau kev xa cov khoom siv hmoov, xws li mis hmoov, hmoov nplej, hmoov nplej, mis tshuaj yej hmoov, dej haus, kas fes hmoov, qab zib, qabzib hmoov, khoom noj khoom haus additives, pub, tshuaj raw khoom, tshuaj tua kab, dyes, flavors, thiab fragrances.

Daim ntawv thov

Kev piav qhia

Lub raj mis Capping Tshuab yog lub tshuab capping tsis siv neeg los nias thiab ntsia hlau hau ntawm lub raj mis. Nws yog tshwj xeeb tsim los rau kev ntim khoom tsis siv neeg. Sib txawv rau cov tsoos intermittent hom capping tshuab, lub tshuab no yog hom capping txuas ntxiv. Piv nrog rau kev sib tshuam capping, lub tshuab no ua haujlwm zoo dua, nias kom nruj dua, thiab ua rau muaj kev phom sij tsawg dua rau lub hau. Tam sim no nws tau dav siv hauv zaub mov, tshuaj, ua liaj ua teb, tshuaj,

tshuaj pleev ib ce kev lag luam.

Nta

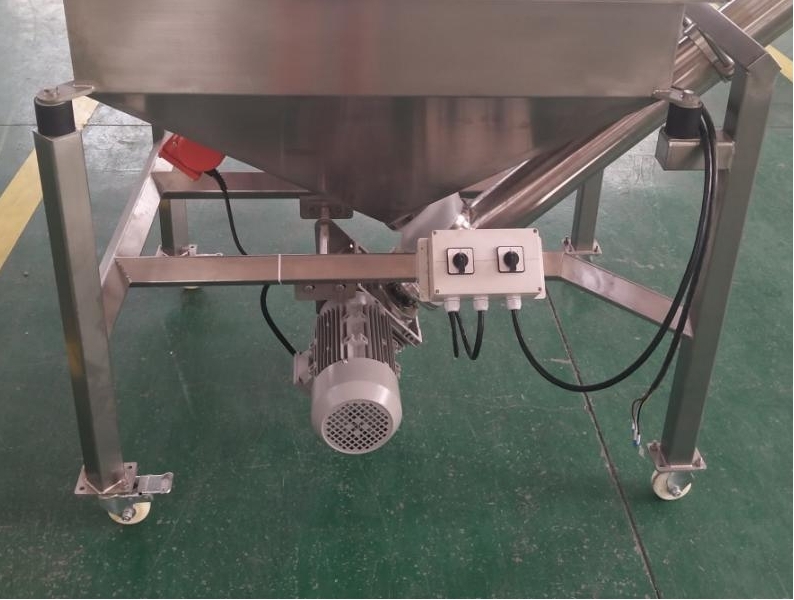

1.Hopper yog vibratory uas ua rau cov khoom ntws yooj yim.

2.Simple qauv nyob rau hauv linear hom, yooj yim rau installation thiab txij nkawm.

3.Lub tshuab tag nrho yog ua los ntawm SS304 kom ncav cuag qib zaub mov thov.

4.Adopting ntiaj teb no nto moo hom khoom nyob rau hauv pneumatic qhov chaw, hluav taws xob qhov chaw thiab ua hauj lwm qhov chaw.

5.High siab ob chav crank los tswj qhov tuag qhib thiab kaw.

6.Running nyob rau hauv lub siab automation thiab intelligentialize, tsis muaj kuab paug

7.Thov ib tug linker mus txuas nrog cov cua conveyor, uas yuav ncaj qha inline nrog filling tshuab.

Paub meej

C.Ob lub cev muaj zog: ib qho rau cov ntsia hlau pub, ib qho rau hopper lub vibrating.

D.Cov yeeb nkab conveying yog stainless hlau 304, tag nrho vuam thiab daim iav polishing. Nws yog ib qho yooj yim los ntxuav, thiab tsis muaj qhov muag tsis pom qhov chaw nkaum cov khoom.

E.Qhov chaw nres nkoj residue nrog lub qhov rooj nyob hauv qab ntawm lub raj, ua kom yooj yim los ntxuav cov seem uas tsis muaj dismantle.

F.Ob lub keyboards ntawm lub feeder. Ib tug tig lub auger, ib tug vibrate lub hopper.

G.Tnws tuav nrog lub log ua rau lub feeder txav tau kom haum rau cov khoom zoo.

Specification

| Main Specification | HZ-2A2 | HZ-2A 3 | HZ-2A5 | HZ-2A 7 | HZ-2A 8 | HZ-2A12 | |

| Lub peev xwm them nqi | 2 m³ / h | 3 m³ / h | 5 m³ / h | 7 m³ / h | 8 m³ / h | 12 m³ / h | |

| Txoj kab uas hla | Φ102 | Ib 114 | Ib 141 | Ib 159 | Ib 168 | Ib 219 | |

| Hopper Volume | 100 L | 200 L | 200 L | 200 L | 200 L | 200 L | |

| Fais fab mov | 3P AC208-415V 50/60HZ | ||||||

| Tag Nrho Lub Zog | 610w ua | 810 wb | 1560 W | 2260 wb | 3060 wb | 4060 wb | |

| Qhov hnyav tag nrho | 100 kg | 130 Kg | 170 Kg | 200 Kg | 220 Kg | 270 Kg | |

| Zuag qhia tag nrho Dimensions ntawm Hopper | 720 × 620 × 800 hli | 1023 × 820 × 900 hli | |||||

| Charge Qhov siab | Standard 1.85M, 1-5M tuaj yeem tsim thiab tsim | ||||||

| Lub kaum ntse ntse | Standard 45 degree, 30-60 degree kuj muaj | ||||||

Kev tsim khoom thiab kev ua haujlwm

Txog Peb

Shanghai Tops Group Co., Ltdyog cov chaw tsim khoom rau cov hmoov thiab granular ntim tshuab.

Peb tshwj xeeb hauv kev tsim, tsim, kev txhawb nqa thiab kev pabcuam ua tiav kab ntawm cov tshuab rau ntau hom hmoov thiab cov khoom siv granular, Peb lub hom phiaj tseem ceeb ntawm kev ua haujlwm yog muab cov khoom uas muaj feem xyuam rau kev lag luam zaub mov, kev lag luam kev lag luam, tshuaj lom neeg kev lag luam, thiab chaw muag tshuaj thiab lwm yam.

Peb muaj nuj nqis rau peb cov neeg siv khoom thiab tau mob siab rau kev tswj hwm kev sib raug zoo los xyuas kom muaj kev txaus siab txuas ntxiv thiab tsim kev sib tw yeej-yeej. Cia peb sib zog ua ke thiab ua kom muaj kev vam meej ntau dua yav tom ntej!

Factory Show

Peb Pab Pawg

Peb Daim Ntawv Pov Thawj

FAQ

Q1: Cov ntaub ntawv dab tsi tuaj yeem ua tus ntsia hlau conveyor?

A1: Cov ntsia hlau conveyors tsim nyog rau kev thauj khoom ntau yam, suav nrog hmoov, granules, me me, thiab txawm tias qee cov khoom siv ib nrab. Piv txwv xws li hmoov nplej, nplej, cement, xuab zeb, thiab yas pellets.

Q2: Lub hau ntswj conveyor ua haujlwm li cas?

A2: Cov ntsia hlau conveyor ua haujlwm los ntawm kev siv lub tshuab helical ntsia hlau (auger) hauv ib lub raj lossis lub trough. Raws li cov ntsia hlau tig, cov khoom raug txav raws li cov khoom siv los ntawm qhov nkag mus rau qhov hluav taws xob.

Q3: Dab tsi yog qhov zoo ntawm kev siv cov ntsia hlau conveyor?

A3: Qhov zoo muaj xws li:

- Kev tsim qauv yooj yim thiab muaj zog

- Ua haujlwm tau zoo thiab tswj cov khoom thauj

- Versatility hauv kev tuav cov khoom sib txawv

- Customizable rau cov ntawv thov tshwj xeeb

- Cov kev tu ncua tsawg kawg nkaus

-Cov qauv tsim los tiv thaiv kev sib kis

Q4: Cov ntsia hlau conveyor puas tuaj yeem tuav cov khoom ntub lossis nplaum?

A4: Cov ntsia hlau conveyors tuaj yeem tuav qee cov ntaub ntub dej los yog nplaum, tab sis lawv yuav xav tau kev tsim tshwj xeeb xws li txheej cov ntsia hlau nrog cov ntaub ntawv uas tsis yog lo los yog siv cov ribbon ntsia hlau tsim los txo qhov txhaws.

Q5: Yuav ua li cas koj tswj tus nqi ntws hauv cov ntsia hlau conveyor?**

A5: Tus nqi ntws tuaj yeem tswj tau los ntawm kev kho qhov kev sib hloov ceev ntawm cov ntsia hlau. Qhov no feem ntau yog ua tiav siv qhov sib txawv zaus tsav (VFD) los hloov lub cev muaj zog.

Q6: Cov kev txwv ntawm cov ntsia hlau conveyors yog dab tsi?

A6: Cov kev txwv muaj xws li:

- Tsis haum rau kev thauj mus los ntev heev

- Nws tuaj yeem hnav thiab tsim kua muag nrog cov ntaub ntawv abrasive

- Tej zaum yuav xav tau lub zog ntau dua rau cov khoom siv hnyav lossis cov khoom hnyav

- Tsis zoo tagnrho rau kev tuav cov khoom tawg yooj yim vim muaj peev xwm tawg

Q7: Koj ua li cas tuav lub ntsia hlau conveyor?

A7: Kev saib xyuas yuav tsum tau kuaj xyuas thiab lubrication ntawm cov bearings thiab tsav cov khoom, xyuas seb qhov hnav ntawm cov ntsia hlau thiab lub raj, thiab xyuas kom meej tias lub conveyor huv si thiab tsis muaj qhov thaiv.

Q8: Cov ntsia hlau conveyor puas siv tau rau kev nqa ntsug?

A8: Yog, ntsia hlau conveyors siv tau rau ntsug nqa, tab sis lawv feem ntau hu ua ntsug ntsia hlau conveyors lossis ntsia hlau elevator. Lawv yog tsim los txav cov ntaub ntawv vertically los yog nyob rau hauv siab inclines.

Q9: Dab tsi yuav tsum tau xav txog thaum xaiv cov ntsia hlau conveyor?

A9: Cov yam ntxwv uas yuav tsum tau txiav txim siab suav nrog hom thiab cov khoom ntawm cov khoom yuav tsum tau thauj, lub peev xwm xav tau, qhov deb thiab lub kaum sab xis ntawm kev thauj mus los, qhov chaw ua haujlwm, thiab txhua yam kev cai tshwj xeeb xws li kev huv lossis kev tiv thaiv corrosion.